|

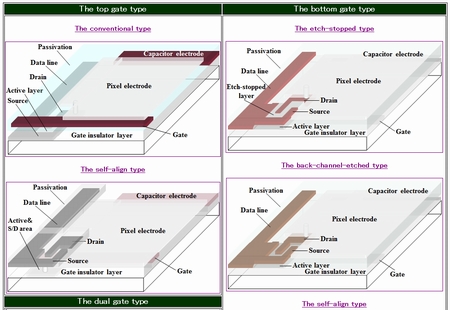

■Structure of oxide-TFT-LCD

Orientation and feature of oxide TFT

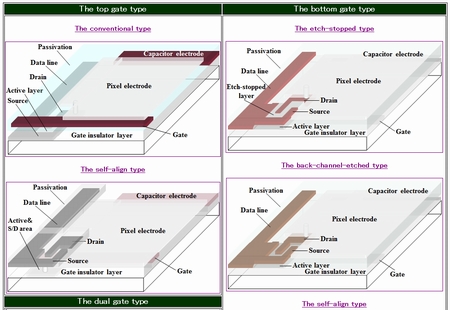

Categorization of oxide TFTs

The top gate type

The conventional type

The self-align type

The bottom gate type

The etch-stopped type

The back-channel-etched type

The self-align type

The dual gate type

■Oxide-TFT array process

Forming process of gate electrode

Forming process of gate insulator film

Forming process of oxide semiconductor layer

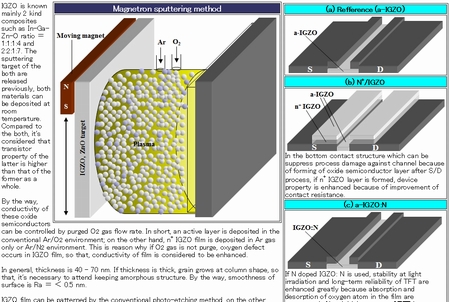

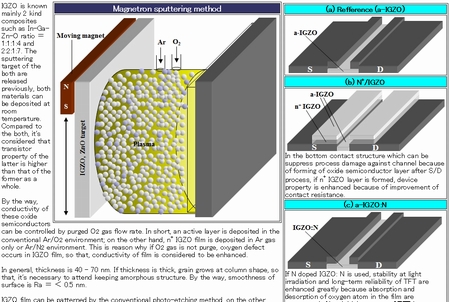

Structure of oxide semiconductor layer

Deposition process of oxide semiconductor layer

Patterning process of oxide semiconductor layer

Direct printing of oxide semiconductor layer

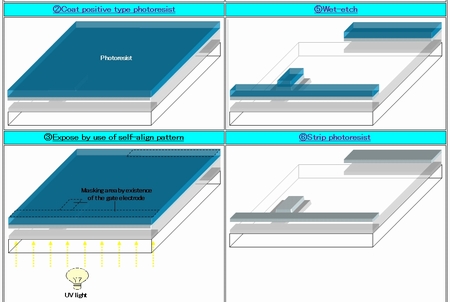

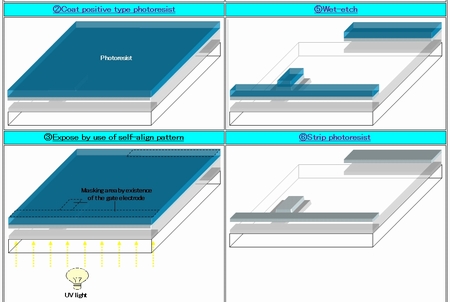

Forming process of etch-stopped layer

Forming process of S/D

Forming process of passivation layer (+ planarization layer) and contact hole Anneal treatment

Forming process of pixel electrode

In case of use of inorganic transparent pixel electrode

In case of use of wettable material

Forming process of source/drain area

Forming process of top gate electrode

■CF (Color filter) forming process

Manufacturing process of CF for IPS mode/FFS mode TFT-LCD

Manufacturing process of CF for VA mode TFT-LCD

Manufacturing process of CF for TN/OCB mode TFT-LCD

Black matrix forming process

Manufacturing process of R, G, B color layer

Manufacturing process of overcoat layer

Deposition process of opposite electrode

Manufacturing process of post-spacer

Manufacturing process of rib (bump)

Photo-alignment process (for MVA mode TFT-LCD)

■LC cell process

Polyimid coating process

Alignment process

Seal layer forming process

Dispersion process of spacer-ball

Making panel thinner process

Scribe and break process

Filling process of LC material

ODF (One drop fill) process

■Module assemble process

Connect panel and driver-IC

■Liquid crystal material and display mechanism

■Structure of backlight module

Side light type

Light guide plate technology

Structure of direct type

LED backlight for TV (Direct type, side light type)

■Liquid crystal material and display mechanism

■3D technology

Method to use a specific glasses

LC shutter glasses method (Time sequential method)

Polarized glasses + patterned phase difference film (Space division method)

Specific glasses-free method

Parallax barrier method

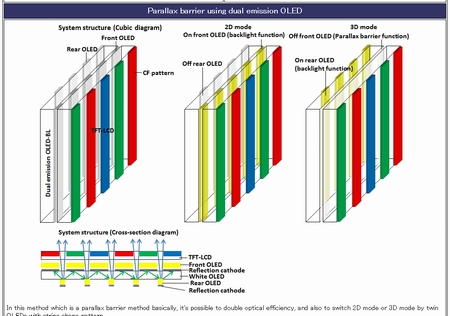

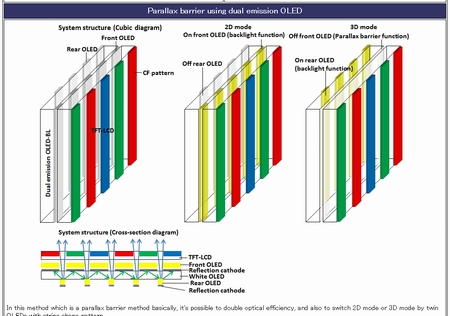

Parallax barrier using dual emission OLED

Time sequential driving + parallax LC barrier method

Lenticular lens method

Time sequential twin-lens 3D-OCB method

Lenticular + time sequential scanning backlight method |

▲TFT structure

▲Self-alignment exposure process of the etch-stopped type TFT

▲Structure of IGZO semiconductor layer

▲3D technology (Parallax barrier using dual emission OLED)

|